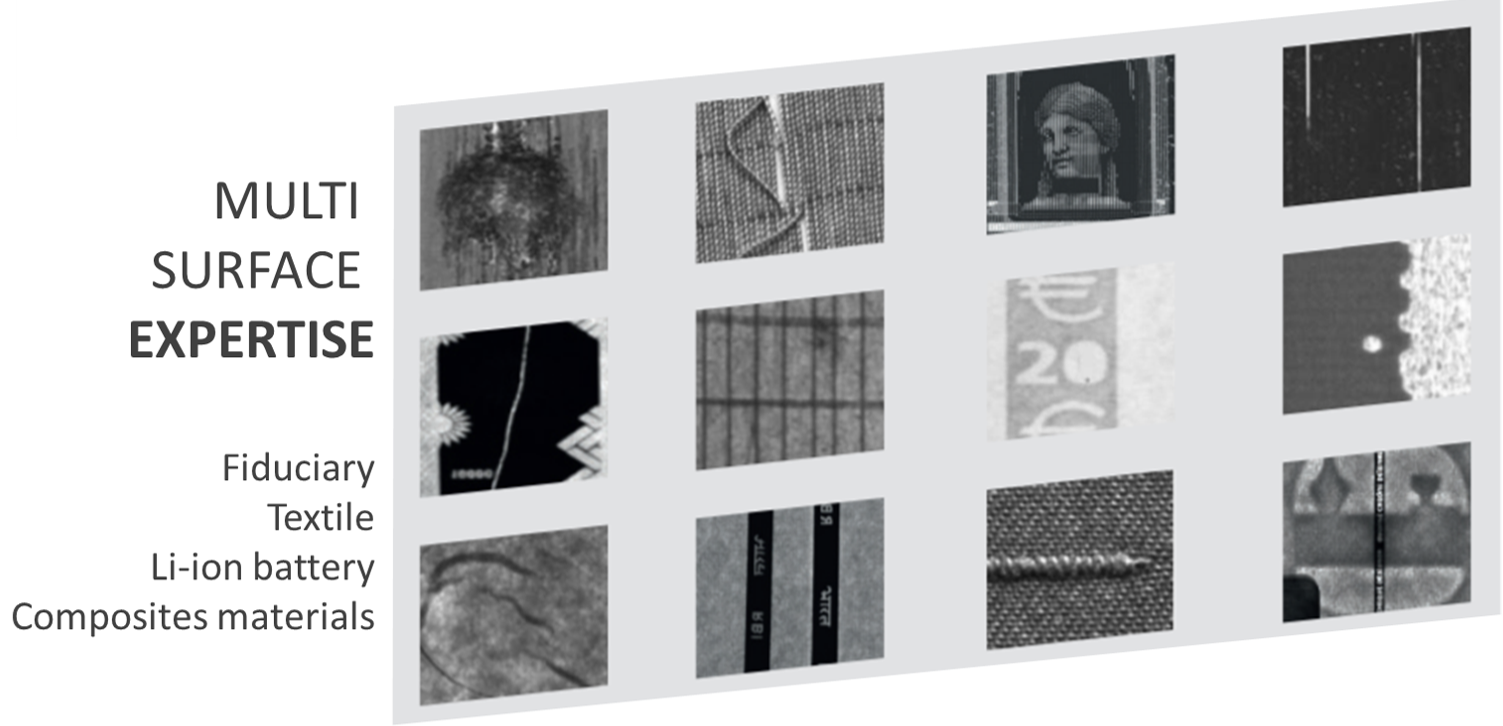

IN-CORE Systèmes proposes the Lineavision solution. A high-resolution camera-based solution for defect identification, process synchronization and live display.

Using the latest technology of high-speed line scan cameras and lightning, the system catches all surface defects, monitors structural distortions and checks surface flatness and width regularity.

Accurate quality control and defect management as well as process monitoring can be easily be performed at each step of the process through continuous automatic inspection of the product.

When the cost of defects is expensive and quality standards are high, Lineavision inspection stations are an optimal control strategy to face the main challenges of the manufacturing products of high valuated surfaces.

Lineavision applications are:

- Fiduciary (banknote and passport production)

- Ulta security substrate making (paper, polymer)

- Ultra security printing (roll to roll, roll to sheet, sheet to sheet, final banknote)

- Composites materials for aerospace applications

- Printed electronics

- Li-ion batteries

- …and others…

More information about High Resolution Inspection Systems ?

Please feel free to contact us !