BATTERY LI-ION

Our expertise in the battery industry

Pioneering Digitalization in battery manufacturing since 2005

At IN-CORE Systèmes, we take immense pride in our contributions to the digitalization of the battery industry. With over 20 years of experience, we have been actively involved in the battery sector since 2005, providing cutting-edge solutions at the electrode manufacturing level.

Innovative Solutions for Enhanced Efficiency and Quality

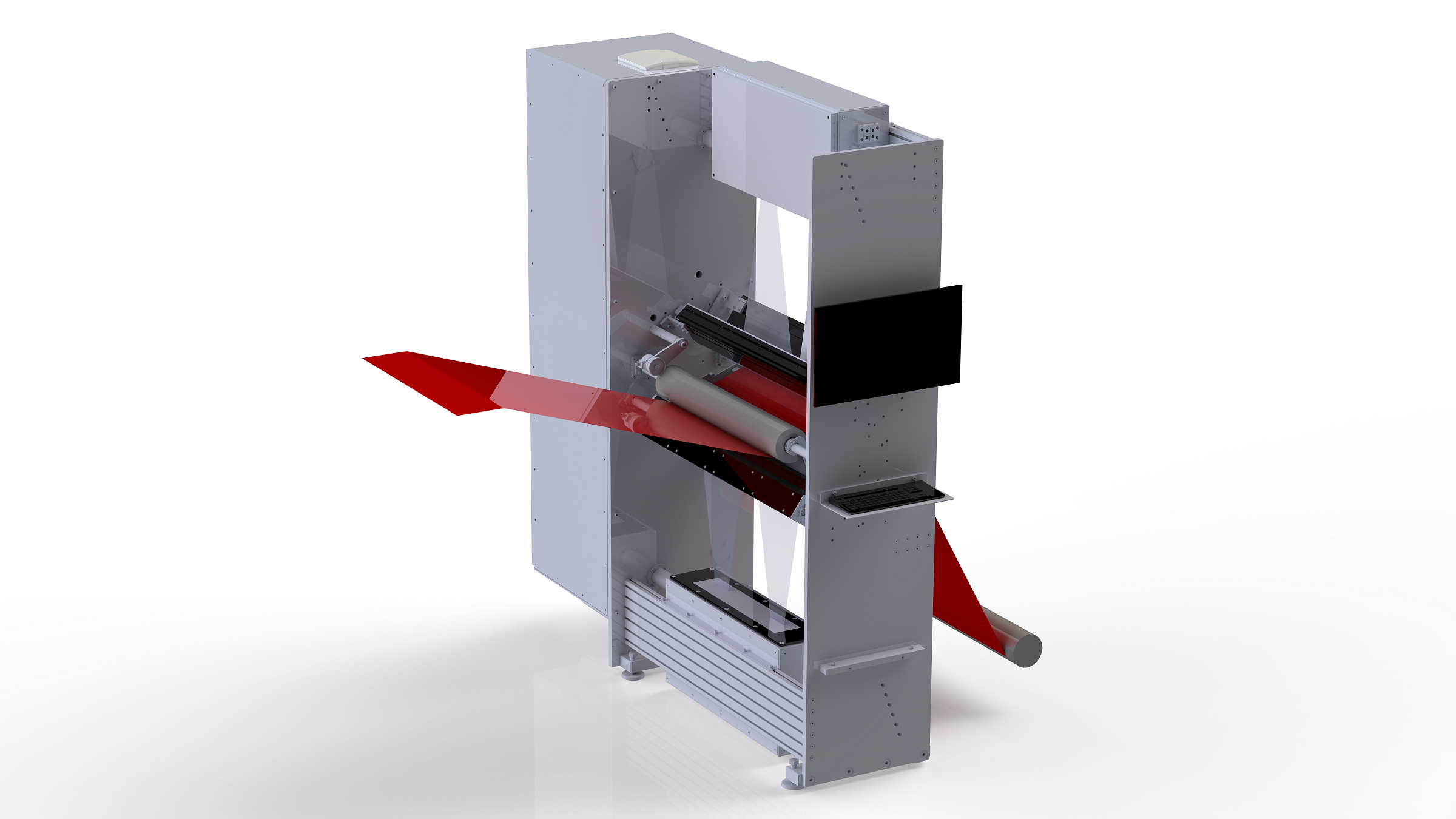

With our in-line inspection solutions for defect detection and dimensional control during the electrode manufacturing process (coating, calendering, slitting), we empower battery manufacturers to accelerate start-up, increase yield, and ensure the highest levels of quality. Real-time data information enables swift detection of process drift, enabling close-loop control and immediate corrective actions from operators, thereby minimizing scrap and optimizing production efficiency.

Empowering Data-Driven Decisions with Individual Electrode Traceability

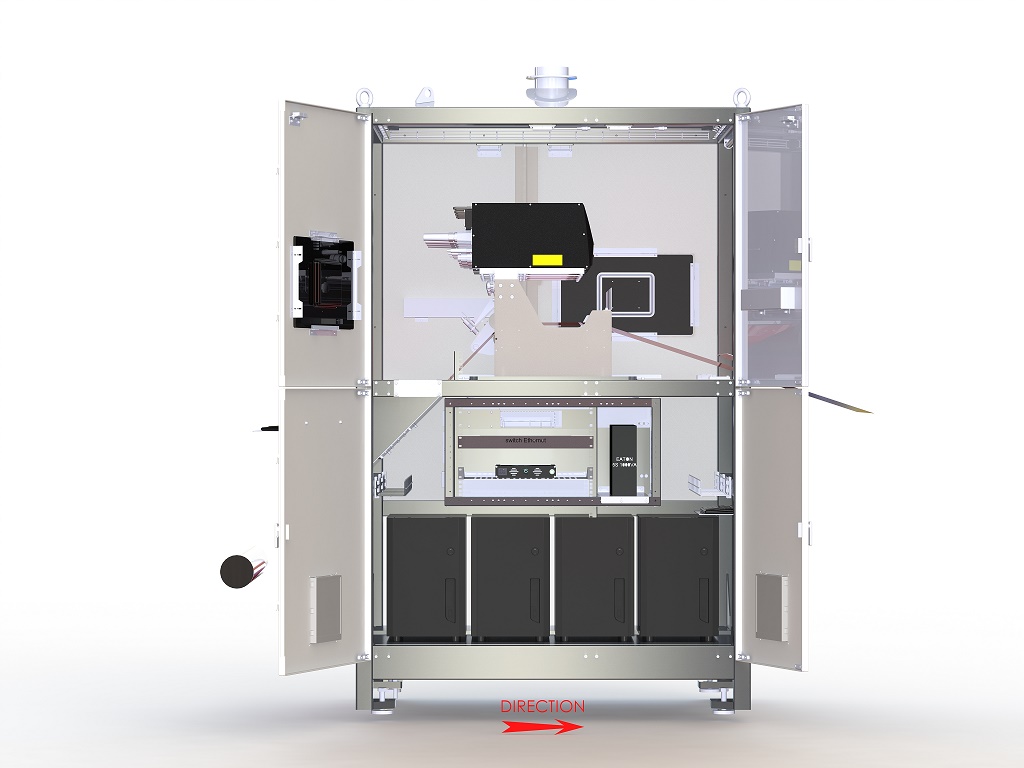

IN-CORE Systèmes understands the significance of data in driving impactful decisions. That’s why our individual electrode traceability solutions, encompassing 2D code marking systems, data collection, and contextualized data acquisition and storage, empower manufacturers to identify and segregate defective electrodes prior to cell assembly. By facilitating quick root cause investigations of battery performance issues, our solutions enable process improvement through data-driven analysis, ultimately leading to superior battery products.

Our expertise

- Expertise in real-time operational systems implementation on the shop floor.

- Having a cross-sectional view of all manufacturing processes to build a solution that will be coherent end-to-end.

- Expertise in contextualized data acquisition and storage in order for information to be valuable and processable for MES.

A Strategic Partnership for Long-term Success

Our philosophy at IN-CORE Systèmes revolves around being a strategic partner to our customers. We believe in forging win-win long-term partnerships, working closely with end-user, different OEMs, implementing solutions in new or existing production lines, and collaborating at various levels, including R&D, pilot, and full-scale production capacities.

As pioneers in the battery industry’s digital transformation, we are committed to pushing boundaries, driving innovation, and empowering manufacturers with state-of-the-art solutions that not only meet current challenges but also prepare them for a thriving future.

Join us in shaping the future of battery manufacturing with IN-CORE Systèmes – Your Partner in Progress.