Lineavision ®

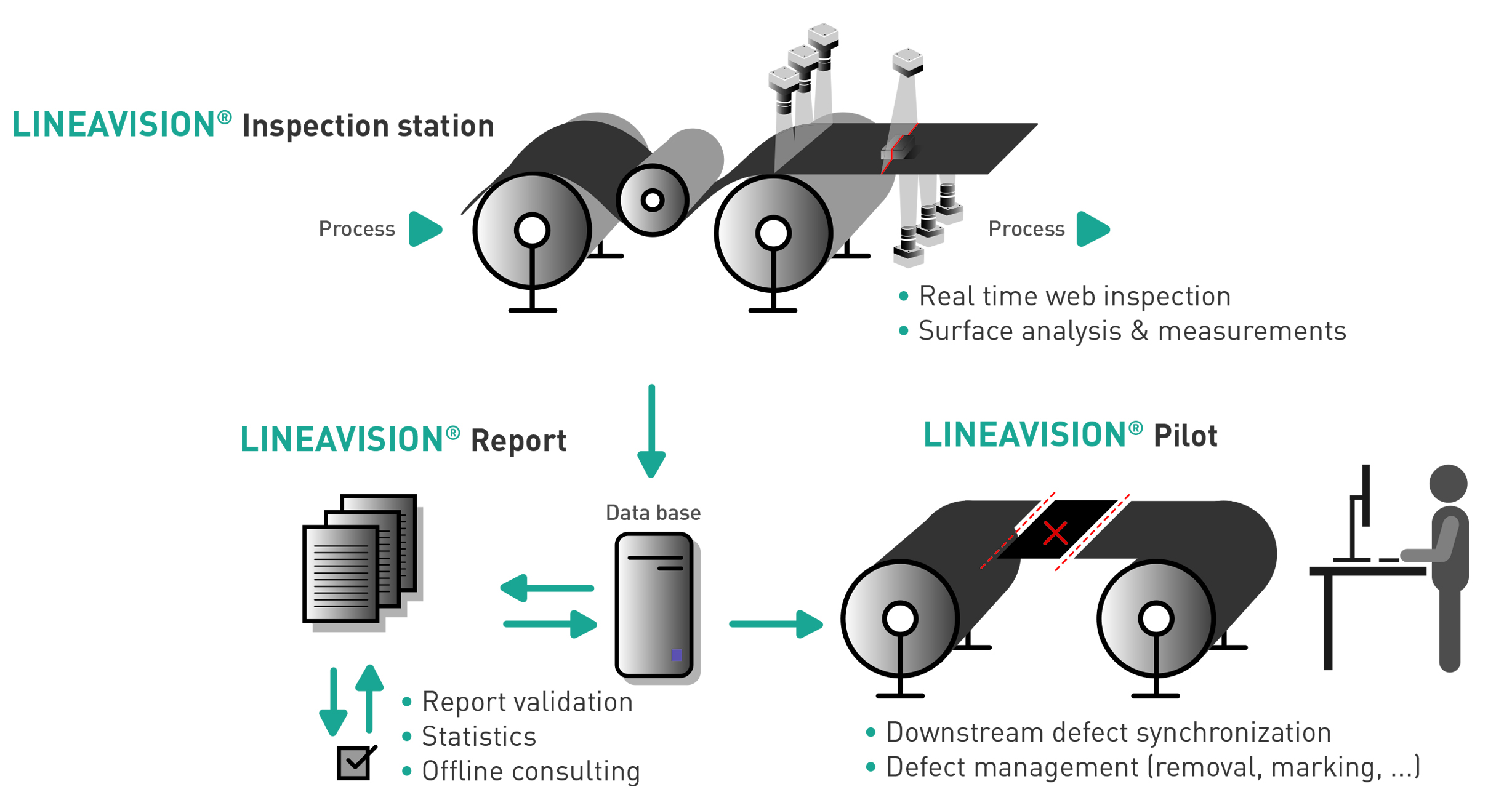

Lineavision ®, In-Line industrial vision inspection solution for global defect management during the manufacturing process.

Lineavision® in-line solution is optimally suited for:

- Plain surface analysis

- Printed patterns regularity and conformity check

- High accuracy measurements of surface characteristics

- Defects analysis and identification

- Global data management

Lineavision solutions contains also post process software tools for:

- statistics,

- defect management,

- summary sheets,

- reports per date,

- batches, rolls, references, etc…

Automated surface inspection and calibrated measurements are essential to minimize process variation influence and help the production to be repeatable, repeatable and repeatable…

Great gains in productivity are achieved, yield optimization is guaranteed, and waste minimized.

Main industries and applications field of Lineavision are:

- Fiduciary (banknote and passport production),

- Ultra-security paper,

- Ultra-security printings,

- Composites materials (woven and UD carbon for aerospace applications),

- Energy (separator and electrodes of Lithium-ion batteries),

- Printed electronics (organic photovoltaic, RFID, flexible circuits, organic sensors, etc.)

- Technical high valuated surfaces (fabric, plastic, glass, ….).