04/02/2021

What is happening in Europe?

Electromobility is a priority for the EU in order to achieve the climate and environmental targets to reduce 90% of CO2 emissions by 2050.

Battery Production capacity in Europe should increase from few GWh in 2019 to + 100 GWh in 2023 and 150-200 GWh in 2025.

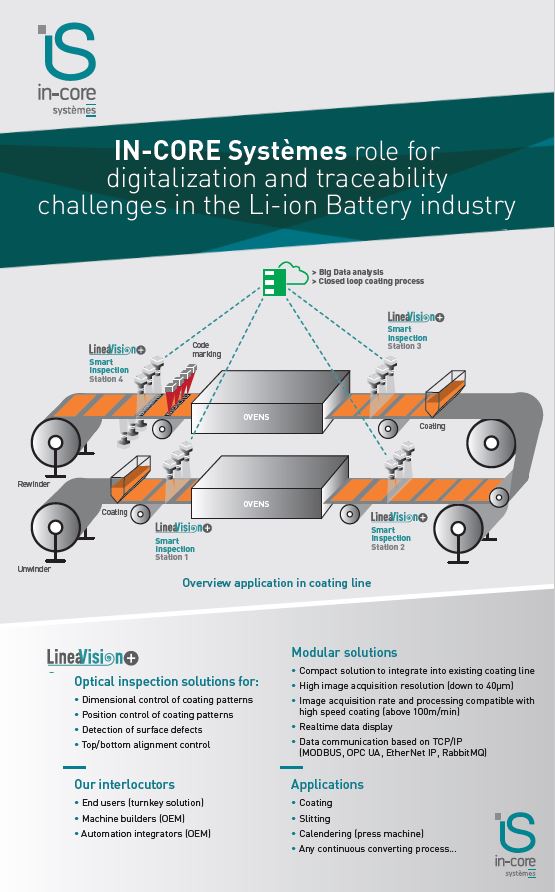

Our contribution

We believe in our contribution to lead the battery industry towards 4.0 revolution! We provide solutions for:

In-line quality control: coating quality and uniformity/regularity (defects as : bubbles, agglomerates, coating free area (pinhole, …), scratches, streaks, micro cracks).

Digitalization: live data broadcast based on user setting.

Traceability: code generation, code marking and code reading. Link between the code and the measured coating characteristics

Our solutions integrated in the production lines and connected to the factory automation system, contribute to make more efficient, sustainable and intelligent the battery manufacturing industry.

How is this is possible?

Thanks to:

- Maximization of productivity, reducing waste and costs

- Batch to batch manufacturing repetitiveness control

- Characterization of nominal process and detection of manufacturing variabilities

- Early detection of defects enabling root cause analysis

Digitalization is the key

Digitalization is key factor to face the challenges of the Battery value chain industry. Digitalized manufacturing together with data analysis of the battery performance will as well contribute to produce better battery packs with longer lifecycle.

Keep us in mind and contact us if you wish to have more information!