Enhanced traceability T+Q

The IN-CORE traceability solution integrates IN-CORE Lineavision’s real-time quality inspection data and guarantees interconnection with external software or machines.

With our expertise we can help the converting industry to build trust on all the collected data and to learn how to exploit it to improve efficiency in the future of converting

IN-CORE Systèmes solution in the Banknote industry

As a front player for quality control and full traceability of security paper and finished banknotes, through various techniques, equipment and algorithms, we use experienced vision engineering capabilities to enhance systems to their full potential. By implementing well-designed in-line vision systems and machine process control, feedback is enhanced to provide all the data needed.We have extensive capabilities in the particular field of produced sheets at the security paper making level providing a reliable solution to the banknote manufacturers.

IN-CORE Systèmes role towards the 4th revolution in the manufacturing process of banknotes consists on providing an integral and modular solution for automatic traceability, quality control and banknote conformity checking throughout all the manufacturing steps. Big Data management solution can be integrated on decision making to improve banknotes’ manufacturing effectiveness. Dimensions and backup time can be adapted to the required level of security of the manufacturer.

What is Enhanced Traceability ?

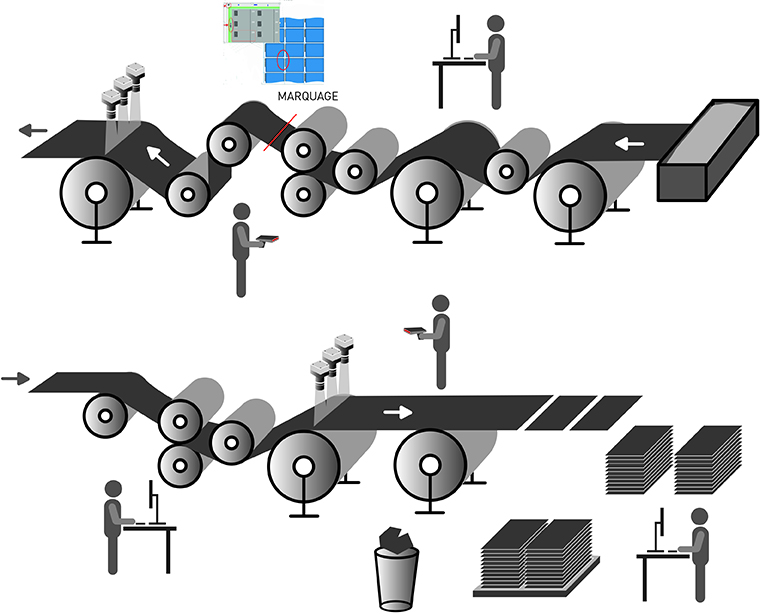

IN-CORE Systèmes, marking and tracing flexible solution (MTS):

IN-CORE Systèmes, marking and tracing flexible solution (MTS):

localization and traceability in real time of all produced sheet at the paper making level:

- Comprehensive code identification marking & reading solution

- Full traceability with quality status at each process step

- Flexible solution, highly adaptable to specific manufacturing processes

- Data consolidation and alarms management

IN-CORE Systèmes traceability solution allows a continuous exchange of data collected during the banknote production paper mill, printing works and central banks.

In an industry deeply engrained to traditions and habits, the role of IN-CORE Systèmes is to build trust on all the collected data and to learn to exploit the data for future banknotes production.

More information about Enhanced Traceability T+Q and/or High Resolution Inspection Systems ?

Please feel free to contact us !