In-Core Systèmes inspections solutions at Northvolt

Partnership between In-Core Systèmes and NorthVolt Labs is confirmed for in-line quality control in the manufacturing process of Li-ion batteries. The LineaVision solutions for battery applications will allow to rapidly and accurately evaluate the quality of the...

African currency Summit 2018

The consistent quality of banknotes is crucial for the acceptance of the notes by the public and their proper functioning in circulation. The definition of measurable quality standards as well as their implementation and monitoring in the production process are...

Openmind: A new generation of minimally invasive devices

The EU funded project OPENMIND has come to an end and presented a new kind of production system for the manufacturing of individualised minimally invasive medical devices fully compatible to MRI technology (Magnetic Resonance Imaging) to open up new perspectives for...

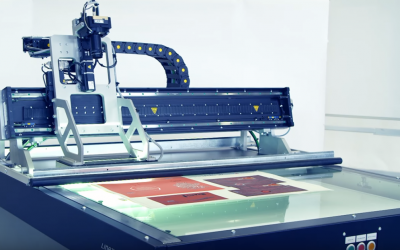

Introducing the smart table solution: offline print qualification equipment

Smart Table The smart table is an offline inspection system dedicated to check a single sheet for print qualification. The system is equipped with multi-acquisition conditions and is fully customized according to the...

In-line inspection for printable Organic/Electronic Materials

Advanced high-resolution printing of organic Transistors for Large Area Smart Surfaces: ATLASS H2020 In-core Systèmes is contributing in the ATLASS H2020 projet, with an in-line inspection solution for printable Organic/Electronic Materials! The ATLASS H2020 project...

Quality Control for Ultra-Security Documents (SDW 2018)

Security Document World (SDW) 2018 Quality control for ultra-security documents IN-CORE Systèmes front-line player for quality control and traceability solutions for ultra-security documents. We are participating at the SDW (Security Document World) at London next...

Introducing the single banknote inspection system

Security features of currency notes has been a main issue in order to make counterfeiting more difficult. At the same time, the improvements in security have increased the production and quality check complexity. Cost-effectiveness of the manufacturing process of...

Real Challenges of in-line control for Lithium-Batteries electrodes

The real challenges of in-line control for Lithium-Batteries electrodes: Manufacturing challenges of Li-ion based batteries. Benefits of in-line vision inspection system in the manufacturing process of Li-ion based batteries. Manufacturing cost optimization is...

INTERGRAF 2018: Security Printing Inspection Solutions

IN-CORE Systèmes, as a leading company in the design and manufacture of automatic inspection systems for ultra-security paper and ultra-security printing industries, has participated in the INTERGRAF Security Printers conference in Dublin from 21 to 23 March 2018. We...

Introducing In-Core Systèmes solution : Automatic batch validation

Evénements

> Evénements • IN-CORE Systèmes participe au salon LOPEC, 7ième salon et conférence internationale pour l'industrie de l'électronique imprimée, du 3 au 5 Mars 2015 à Munich, Allemagne. Rejoignez nous sur le stand 108 Hall B0. • IN-CORE Systèmes sera exposant sur...

Security paper inspection

Banknote, e-passports and security documents Lineavision® for security paper application allows the user to automatically inspect the quality during processing and to continuously check for conformity during the paper making and first level of the securization...

Fabric woven inspection : dyed, plain or printed fabrics

Surface aspect control, weft and warp deviation measurementsLineavision® for woven technical textile inspection enables to have a close look at the technical textile surface manufacturing should it be plain or converted. Accurate quality management and process...

Composite surface inspection

Carbon, Glass, Kevlar, Aramid, in UD or fabric structures Lineavision® for Aerospace applications is used to fulfil the quality standards of major aerospace manufacturers where defects, for security and safety reasons, must be detected, traced and removed....

Plastic film inspection

Surface aspect quality control, width and stretching measurements Surface aspect quality control, width and stretching measurements Lineavision® for plastic film inspection on extrusion and calendring lines enables an optimization of the laminating process. This will...

Automotive industry inspection

Flexible inspection solutions for a wide range of surfaces used in car manufacturing IN-CORE Systèmes provides flexible inspection solutions for a wide range of surfaces used in car manufacturing. Lineavision® for automotive applications enables manufacturers...

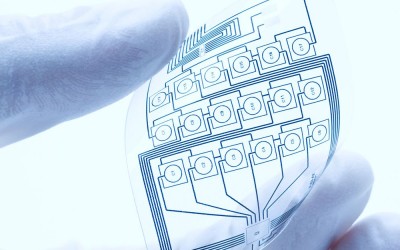

Printed Electronics inspection

Flexible solar cell circuits IN-CORE Systèmes provides unique solutions for flexible printed circuits, based on its expertise in image acquisition. These applications require a very high resolution inspection to avoid short circuits and to ensure: Precise...

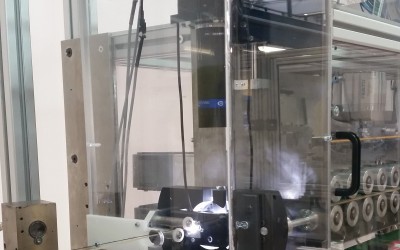

Inspection solutions for Lithium-ion, Lithium-polymer batteries

Anode, Cathode & Separator quality monitoring Lineavision® for battery applications provides flexible inspection and measurement solutions where safety, efficiency and life time of the products are the biggest challenges. The inspection solutions guarantee the...