10/03/2020

IN-CORE Systèmes a front-line player in the ultra-security industry. Leading supplier of in-line and off-line optical solutions for register mark control, printing quality inspection and traceability solutions.

Standalone register mark control equipment

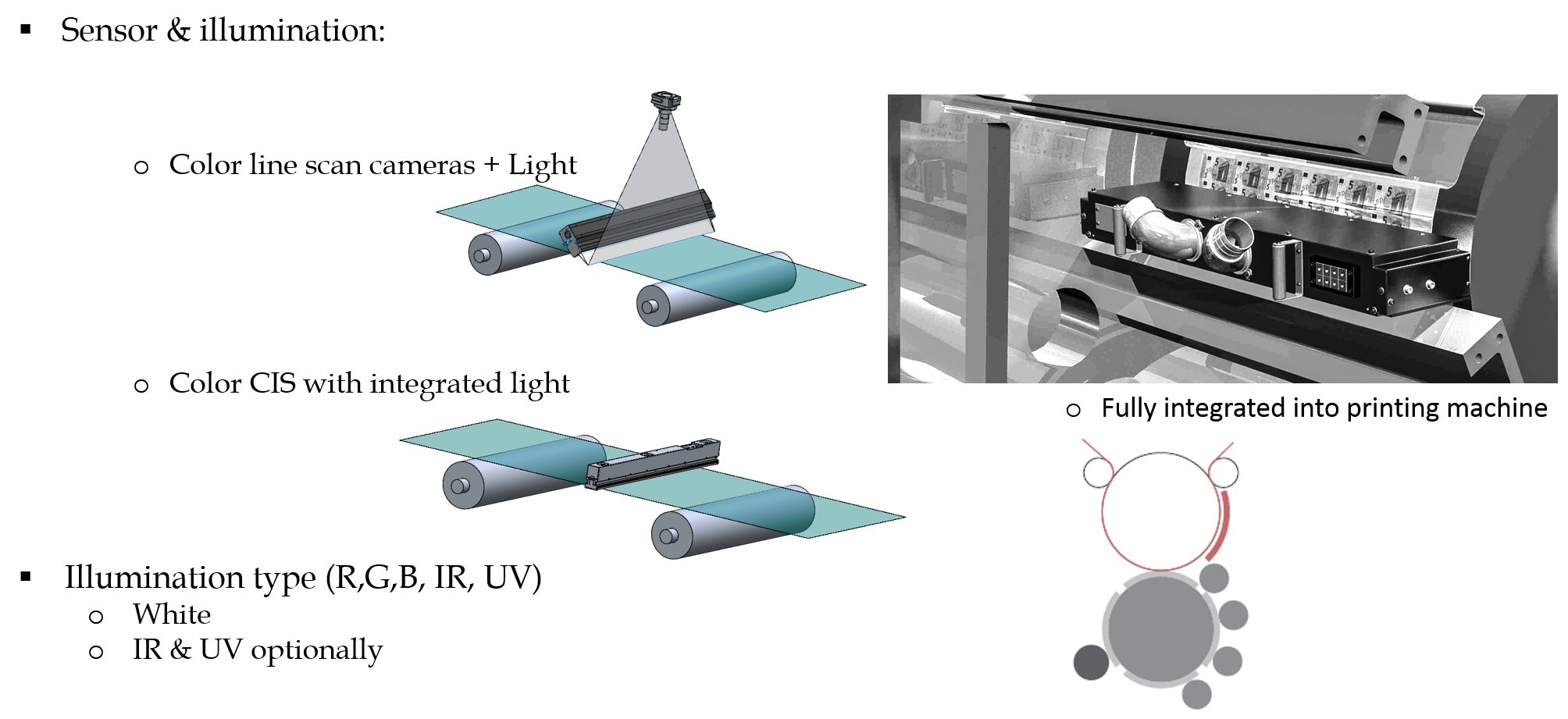

Standalone system based on single colour CIS (contact image sensor) or line scan cameras with adequate lighting, easy to integrate into existing printing machine. The image acquisition is rated through an encoder signal. Standard resolution is 300DPI but up to more.

Register Mark control and web viewing on Intaglio Printing machine

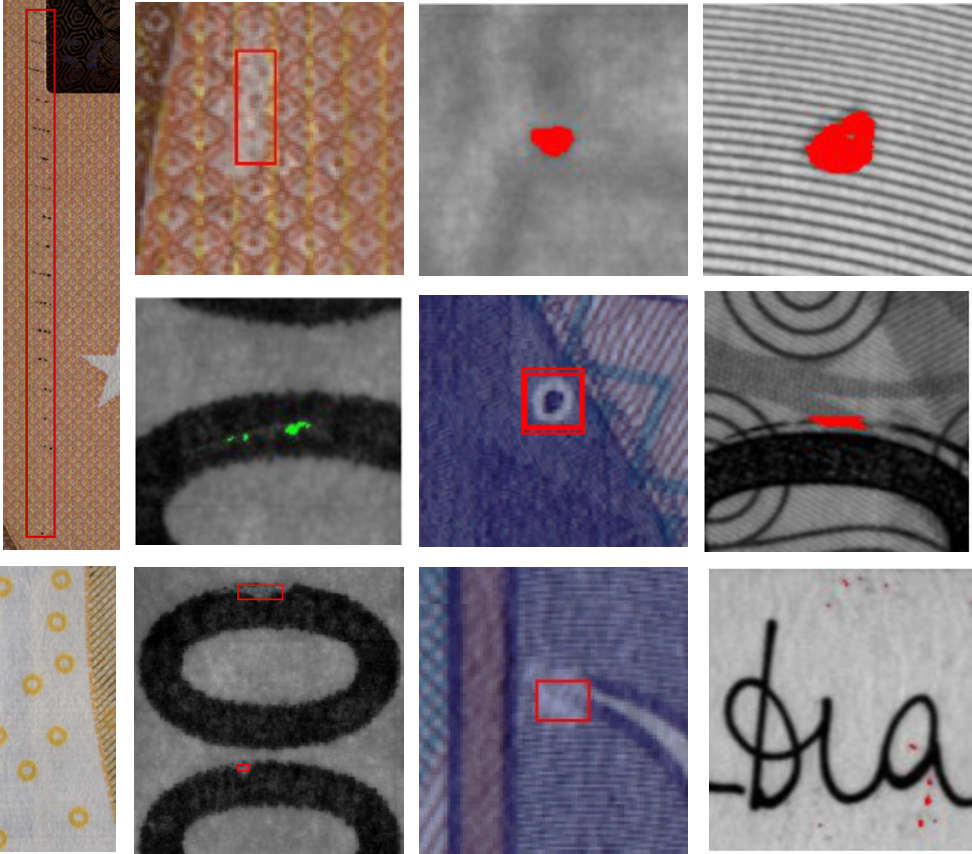

In-line inspection solution built with IN-CORE Systèmes know-how to garantee complete detection and position measurement of:

- intaglio register mark according to offset register mark.

- intaglio register mark according to sheet edge or sheet reference

Closed-loop control system

The equipment for register control has built-in communications functions to automatically achieve and maintain the desired printing registration.

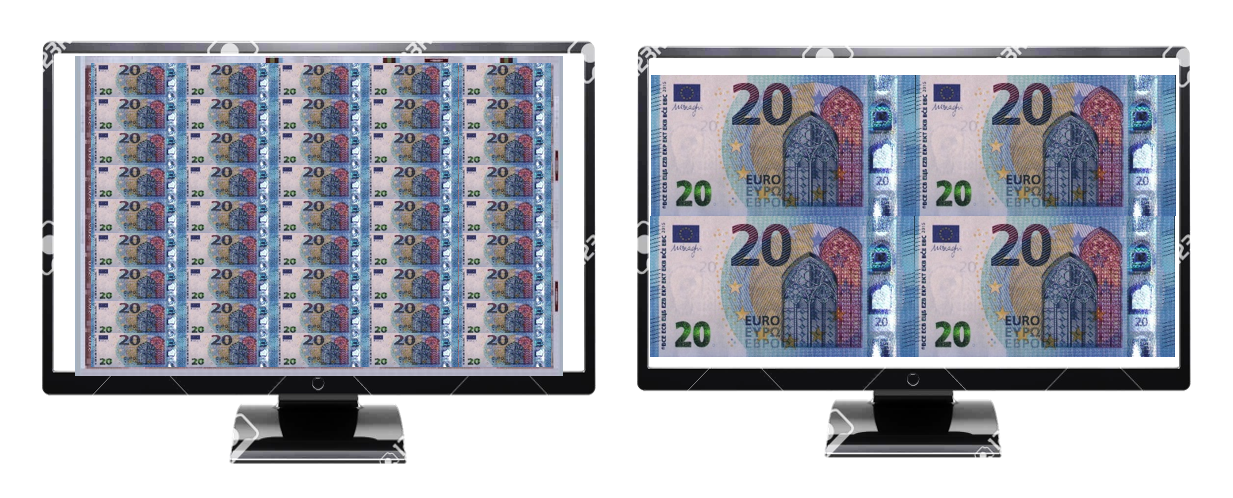

Full visualization possibilities

Display of the whole sheet in synchronized mode with possibility to zoom in/out of zones of interest in all parts of the sheet or to strobe on a fixed position of the sheet (e.g reference marks)

More information about High Resolution Inspection Systems ?

Please feel free to contact us !